Manufacturing of metal products to mee the most stringent requirements in your industry

Precision Metal Solutions provides engineering-grade metal fabrication for demanding industrial and commercial applications.

We specialize in custom-designed components and assemblies, ensuring accuracy, durability, and seamless integration with your existing systems.

From detailed design and prototyping to full-scale production and installation — we deliver results that perform under pressure.

Tailored CNC Machining Services

PMS CNC provides a full spectr of CNC machining services for any manufacturing challenge. Explore our offerings below:

CNC WaterJet cutting

Waterjet cutting is used when other methods — especially thermal cutting — are not suitable due to material distortion or heat effects.

It allows precise cutting of complex shapes without altering the material’s structure or surface.

This process is ideal for metals, stone, glass, ceramics, and composites, delivering clean edges and preserving original material properties.

CNC Plasma cutting

CNC plasma cutting is a cost-effective method for cutting large and thick metal parts.

While it offers lower precision compared to laser or waterjet cutting, it provides excellent speed and efficiency for structural and construction components where high accuracy is not critical.

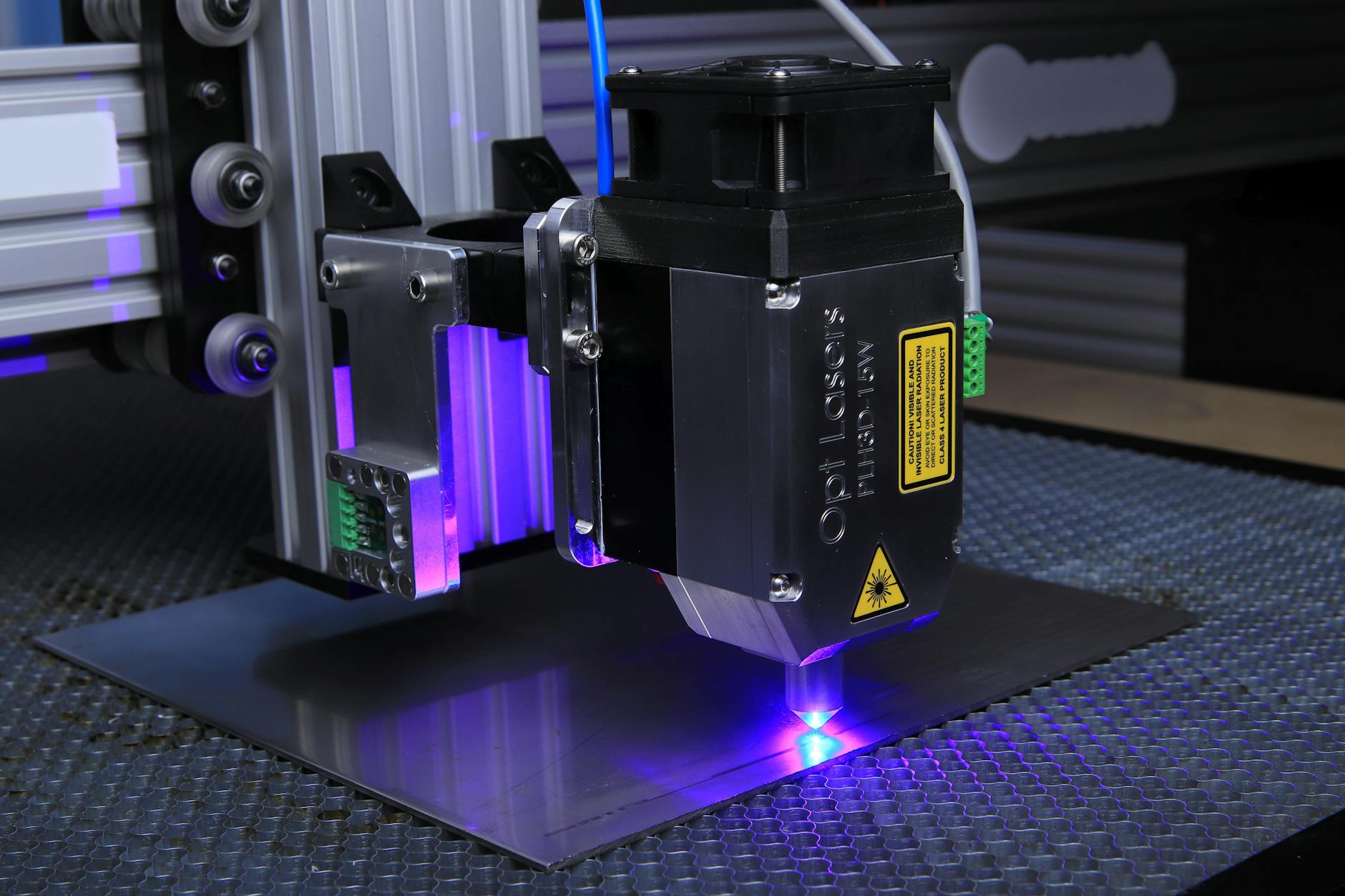

CNC Laser Cutting

CNC laser cutting delivers high precision and clean edges, making it ideal for detailed and complex parts.

This method provides excellent accuracy and minimal material deformation, especially suited for thin metals and decorative components where fine quality is essential.

Design and Prototyping

We take a personalized approach to every project — turning ideas into practical, ready-to-build solutions.

From 3D models and assembly drawings to exploded views and installation plans, our designs make fabrication and installation fast, accurate, and worry-free.

Our goal is simple: deliver precision and meet every client’s need with complete satisfaction.

On-Site Measurement & Design

We provide on-site engineering and design services for industrial, construction, and food-processing facilities.

Our work begins at your location — taking precise measurements, analyzing requirements, and developing custom design solutions that fit your process and environment.

We collaborate closely with project managers, engineers, and plant supervisors to ensure every detail is accurate and fully aligned with operational needs.

From initial site visit to final documentation approval, our goal is to deliver efficient, safe, and ready-to-implement solutions that make installation and production easier.

Why Choose Precision Metal Solutions?

At Precision Metal Solutions, we don’t just make parts — we build trust.

Every project starts with understanding your goals and ends with a solution that fits perfectly.

With a focus on quality, communication, and precision, we make sure every detail works — so you can focus on what matters most.

Unmatched Accuracy

Our state-of-the-art CNC machines deliver tolerances down to the high level, ensuring every part meets your specifications.

Fast Turnaround

With a streamlined workflow and advanced automation, we deliver quality parts without compromising lead times, helping you meet tight deadlines.

Custom Solutions

No two projects are the same. Whether you're prototyping or in full production, we tailor our services to meet your unique needs.

What to Expect Working With Us

Timeline of your past work / experience below

1. Pre-Design Stage

Collecting and organizing client information to clearly define project requirements and ensure an accurate design brief.

2. Design Stage

Developing detailed 3D models, drawings, and technical documentation to guarantee precision and seamless integration during manufacturing and installation.

3. Production Stage

Fabricating components and assemblies with high accuracy and consistent quality, using advanced equipment and proven metalworking techniques.

4. Installation Stage

Performing on-site installation and alignment, ensuring every element fits perfectly and functions as intended.

5. Quality Control & Handover

Conducting final inspection and testing to verify precision, reliability, and compliance with project requirements.

All documentation is finalized and approved before official handover to the client.

Request an Estimate

Tell us about your project! We typically provide quotes within 1-3 business days after receiving information or project details. Our team will review the requirements and get back to you promptly with a detailed cost breakdown.